Researchers have developed a methodology to improve the reversibility and durability of electrodes using bifunctional platinum-nickel alloy catalysts with an octahedral structure that exhibits both oxygen reduction and generation reactions. The study is published in the journal Advanced Energy Materials.

Bifunctional catalysts are a new generation of catalysts that simultaneously produce hydrogen and oxygen from water using a single catalyst.

Currently, electrochemical systems such as water electrolysis technology and CCU (carbon dioxide capture and utilization) utilize separate catalysts for both electrodes, resulting in a high unit cost of hydrogen production. Bifunctional catalysts that can be synthesized in a single production process are attracting attention as a technology that can reduce production costs and increase the economic efficiency of electrochemical energy conversion technologies.

However, the problem with bifunctional catalysts is that after each electrochemical reaction that generates hydrogen and oxygen, the performance of other reactions decreases due to structural changes in the electrode material. Therefore, in order to commercialize bifunctional catalysts, it is important to secure reversibility and durability that can maintain the catalyst structure for a long time after the reaction.

To enhance the reversibility and durability of the bifunctional catalyst, the team synthesized alloy catalysts with different structures by mixing platinum and nickel, which have high performance in oxygen reduction and generation reactions, respectively.

The results showed that the nickel-platinum interaction was most active in the octahedral structure, and the alloy catalysts performed more than twice as well as the platinum and nickel monoliths in oxygen reduction and generation reactions.

The researchers identified platinum oxide generated during the repeated generation reaction of the alloy catalyst as the cause of the performance degradation and developed a structure restoration methodology to reduce platinum oxide to platinum.

The team confirmed through transmission electron microscopy that the methodology restored the catalyst’s shape, and in large-area reactor experiments for commercialization, the team succeeded in restoring the catalyst shape and more than doubled the run time.

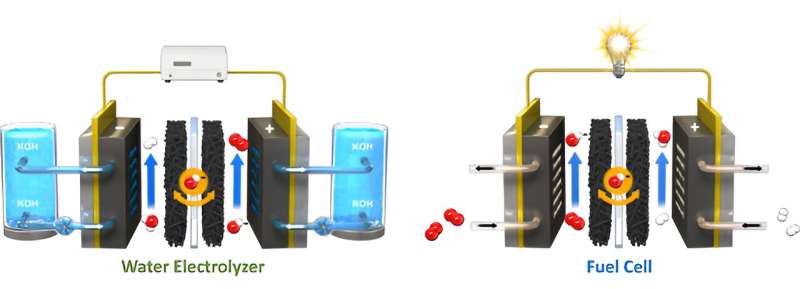

The team’s bifunctional catalysts and structure recovery methodology are expected to accelerate the commercialization of unitized renewable fuel cells (URFCs) technology by replacing the separate catalysts for oxygen evolution and reduction reactions with bifunctional catalysts. URFCs that can produce both hydrogen and electricity can lower production costs by reducing the input of expensive catalysts while maintaining performance.

The research was the result of a collaboration between Dr. Hyung-Suk Oh and Dr. Woong-Hee Lee of the Clean Energy Research Center at the Korea Institute of Science and Technology (KIST) and POSTECH and Yonsei University.

“The technology to improve the reversibility and durability of catalysts has provided a new direction for the development of bifunctional catalysts, which is an important technology for electrochemical energy conversion systems,” said Hyung-suk Oh, lead researcher at KIST.

“It will contribute to the commercialization and carbon neutrality of electrochemical systems such as URFCs in the future.”