Europe needs to take much more decisive action to slash reliance on Chinese rare earths to avert worse supply disruptions, according to a German magnet maker that’s just started a plant in the US.

Vacuumschmelze GmbH’s new facility in South Carolina is among the first to reach production in a planned wave of rare-earth magnet projects in America. Chief Executive Officer Erik Eschen contrasted US efforts to reshore supply chains with what he described as Europe’s far less urgent approach, both from government and in boardrooms.

“There’s a clear difference with the United States, which is leading the whole conversation,” Eschen said in an interview. “I would expect that the European politicians, as well as the industry, fall back into their sleeping mode and just wait for a solution that will come from the US or China.”

China’s export controls on rare earths were President Xi Jinping’s most potent weapon in the recent trade war with the Trump administration. But the curbs also embroiled other major economies, threatening industrial disruptions and spurring discussions about building alternative supply chains now that the two sides have agreed to a truce.

The US government has invested directly in MP Materials Corp. to create a national rare earths champion. It’s funding new domestic processing plants, while pledging cash for mines in Australia and Brazil. Treasury Secretary Scott Bessent, who attended the opening of Vacuumschmelze’s South Carolina plant, has said the US will go at “warp speed” to break its reliance on China.

“There’s a lot of know-how in Europe, but what we see right now is a lot of this is being transferred to the United States, to Canada, to Australia,” Eschen said last week. “We have to do something; otherwise we will lose our know-how, and in the longer term it’ll be disaster for Europe.”

Reliable Access

Vacuumschmelze, founded more than a century ago, has been making rare-earth magnets for more than 40 years. Its plant in Germany buys rare-earth “flake” from China and elsewhere, and uses the intermediate product to turn out the magnets vital for vehicles and electronic goods.

The European Union’s Critical Raw Materials Act, which came into force last year, is the continent’s strongest supply-chain legislation so far. But it’s been criticized for a lack of attention to funding, and the bloc has struggled to reach consensus on how to counter China.

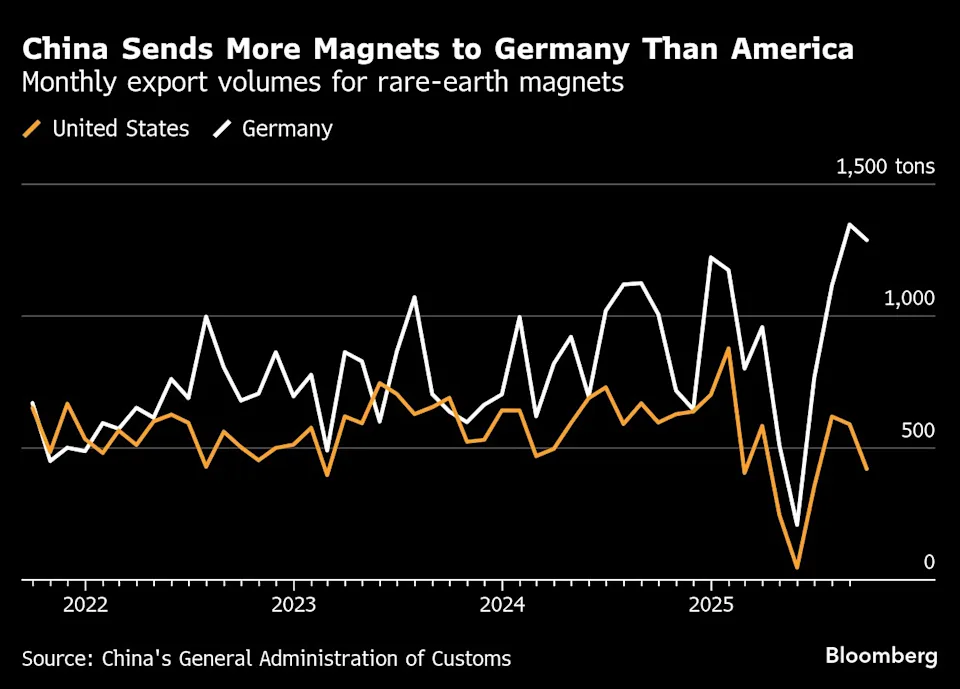

Eschen’s warning comes as Germany — by far Europe’s biggest customer for Chinese magnets — tries to push Beijing for “reliable access” to critical raw materials. Finance Minister Lars Klingbeil said he had received assurances during a visit this week that European concerns about export restrictions “will be taken seriously.”

The German firm’s magnet plant in South Carolina plant has initial capacity of 2,000 tons a year, and is targeting full production in the first quarter of 2026. Capacity could double a year later, on the way to an eventual goal of 12,000 tons.

In neighboring North Carolina, rare-earths startup Vulcan Elements Inc. has announced it will use $1 billion of government funding and private capital to build a facility that the state’s governor said will be the largest magnet factory in the world outside of China.

A major uncertainty in developing alternative supply networks is the extent to which end-users are prepared to forgo China’s formidable ability to meet customer requirements at low cost.

On that front, European companies are lagging their North American counterparts, Eschen said. While some firms, especially those supplying defense industries, are being more pro-active, many others risk losing out in future crises by not securing alternatives to China now.

“If additional customers come on a larger scale, they will have to wait another 12 to 24 months until we have the capacity up and running,” Eschen said. “Until then, they won’t get anything.”