A promising, more durable fuel cell design could help transform heavy-duty trucking and other clean fuel cell applications. Consisting of nanowires that are less susceptible to corrosion than other designs, the innovative electrode—the heart of a polymer electrolyte-membrane fuel cell—could usher in a new era for fuel cells, which use hydrogen as emission-free power for vehicles.

“In real-world terms, this means that we can have a more durable fuel cell that will provide high fuel economy over a longer lifetime,” said Jacob Spendelow, a scientist with the Los Alamos National Laboratory team that described its results in the journal Advanced Materials. “This work demonstrates that we can get rid of conventional carbon-based catalyst supports, eliminating the degradation problems associated with carbon corrosion, while still achieving high fuel cell performance.”

The improved durability makes this fuel cell a promising candidate for use in heavy-duty trucking applications, which require fuel cell lifetimes of more than 25,000 hours.

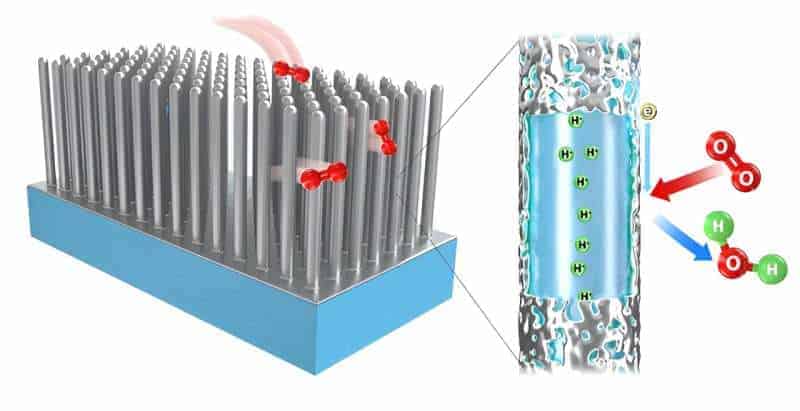

The coaxial nanowire electrode (CANE) consists of an array of vertically aligned nanowires in which each nanowire comprises a catalytically active platinum film surrounding an ion-conducting polymer core. By avoiding carbon-based catalyst supports, the CANE eliminates common degradation mechanisms associated with carbon corrosion.

The team subjected the new fuel cells to accelerated stress tests to assess their durability. The CANE lost only 2% of its performance after 5,000 stress tests cycles focused on the support materials, compared to an 87% loss in performance observed with a conventional carbon-based electrode.

The coaxial nanowire approach is one of several novel fuel cell designs generated at Los Alamos National Laboratory; a grooved electrode design was recently described in Nature Energy.