The demand for electronics has led to a significant increase in e-waste. In 2022, approximately 62 million tons of e-waste were generated, marking an 82% increase from 2010. Projections indicate that this figure could rise to 82 million tons by 2030.

E-waste contains valuable materials such as metals, semiconductors, and rare elements that can be reused. However, in 2022, only 22.3% of e-waste was properly collected and recycled, while the remaining materials, estimated to be worth almost $62 billion, were discarded in landfills.

Although efforts to improve e-waste recycling continue, the process remains labor-intensive, and a significant portion of e-waste is exported to developing countries, where cheap labor supports informal recycling practices involving hazardous chemicals.

In a study published in the journal RSC Advances on 20 September 2024, researchers from Sophia University in Japan and Università di Pavia in Italy have developed a new microwave-induced pyrolysis method that provides an affordable and efficient way to recycle electrical wiring cables.

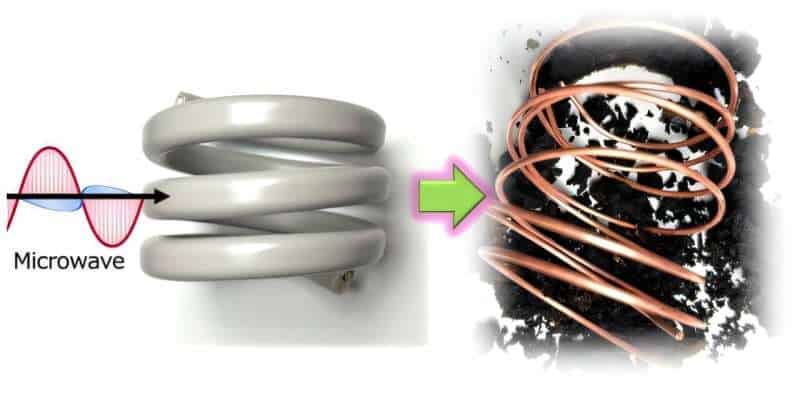

The method carbonizes the PVC insulation and exposes the copper wire without damaging it, allowing for easy recovery without generating highly toxic byproducts.

“VVF cables are commonly used as power cables in houses and buildings and have a high reuse value among e-waste. Our method is suitable for recycling and recovering e-waste containing metals and requires no pre-treatment to separate the plastics from the metals,” says Professor Satoshi Horikoshi from Sophia University, one of the lead authors of the study.

The researchers placed two-core VVF power cables containing two copper wires covered in PVC insulation into a glass reactor and exposed them to microwave radiation of 100, 200, and 300 W. Nitrogen gas was introduced into the reactor to prevent combustion during the pyrolysis process. They tested a standard 54 cm VVF cable and cut pieces of different cable lengths (1 cm, 6 cm, 9 cm, 12 cm, and 18 cm).

Interestingly, the effectiveness of the pyrolysis varied with the cable length relative to the microwave’s wavelength, which was approximately 12.24 cm at a frequency of 2.45 GHz.

Pyrolysis was most effective in cables whose lengths matched specific fractions of the wavelength. The 9 cm (about 3/4 wavelength) and 18 cm cables (longer than the wavelength) began pyrolyzing after 60 seconds at 100 W. In contrast, shorter lengths like the 3 cm cable (about 1/4 wavelength) needed higher power (200 W) to start pyrolysis. Other lengths, such as 1 cm, 6 cm, and 12 cm (whole or nearly whole wavelengths), showed no pyrolysis even at 300 W.

Plastics themselves do not absorb microwaves, but the 9 cm and 18 cm cables underwent pyrolysis for several reasons. First, at these lengths, the copper wires acted as antennas, absorbing microwave radiation and creating electric arc discharges that heated the PVC without melting the copper.

Second, the electric field was stronger and concentrated at the ends and the center of these wires. The 9 cm wire had an electric field strength about twice that of the 3 cm wire, leading to faster and more localized heating. Third, as the PVC heated up and carbonized, it became better at absorbing microwaves, which further accelerated the pyrolysis process.

During the pyrolysis process, the PVC insulation underwent rapid dichlorination and carbonization, which effectively prevented the formation of harmful byproducts such as tar, polycyclic aromatic hydrocarbons (PAHs), and dioxins.

“Chlorine could be recycled as hydrochloric acid; the carbon and activated carbon produced could be recovered as carbon black,” says Prof. Horikoshi.

Since the microwaves were able to heat and break down wires longer than their wavelength, the 54 cm VVF cable was completely pyrolyzed in just 12 minutes under 300 W radiation, leaving the copper wire intact and undamaged.

Currently, only about 35% of PVC insulation is recycled. This microwave-assisted pyrolysis method offers a more efficient, less labor-intensive way to recover copper wires from PVC cables, improving the recycling process and addressing the growing issue of e-waste.