A real-time, 3D temperature map of the inside of a nuclear microreactor for improved safety monitoring was reconstructed using a newly-established theoretical foundation to evaluate basis functions, which can be combined to describe fundamental trends in data, according to a new University of Michigan study.

The results, published in Applied Mathematical Modelling, are applicable wherever “big data” analytics are required as the reconstruction methods are suited for high-resolution distributions in 3D.

“Most work in sparse reconstruction methods focus on time-dependent digital signals, but this study focuses on distributions which exist in physical space,” said Dean Price, a doctoral student of nuclear and radiological sciences at U-M and corresponding author of the study.

While evaluation found that general basis functions are not accurate enough for real-world microreactor temperature monitoring, the team identified ways to improve them.

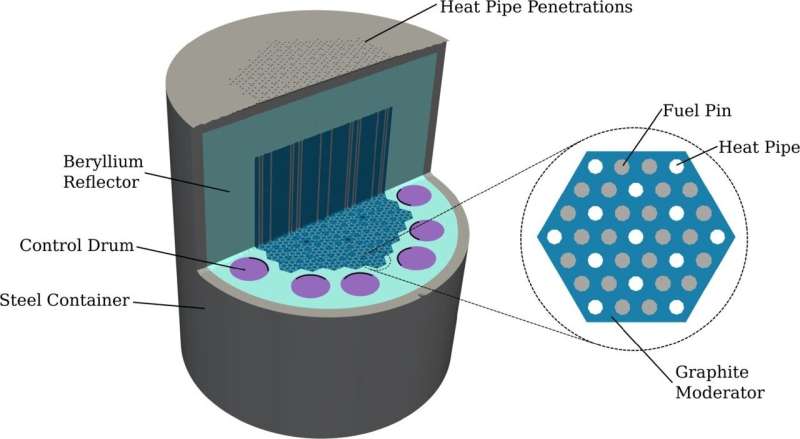

Nuclear microreactors—small nuclear reactors able to be hauled by a semi-tractor trailer—can operate independently or as part of an electrical grid. These compact reactors can generate up to 20 megawatts of thermal energy that can be used directly as heat or converted to electricity.

The lower upfront costs and smaller siting requirements of microreactors should open up new markets for nuclear power, which has significant potential to complement renewable energy in transitioning to a decarbonized electric grid.

“One of the main challenges to achieving this is the ability to ensure that we know what’s going on inside the reactor at any given time,” said Brendan Kochunas, an associate professor of nuclear engineering and radiological sciences at U-M and senior author of the study.

Able to go for years without refueling, nuclear microreactors offer both reliability and operational flexibility for use in natural disaster relief, military operations or remote areas. However, operating in remote areas demands sophisticated monitoring systems to ensure safety.

“Digital twins, meaning a representation of the physical reactor reconstructed from sensor data, are an exciting new prospective technology which may improve both the safety and economic viability of nuclear microreactors,” said Price.

A high-resolution, 3D reconstruction of temperature distributions within a heat pipe nuclear microreactor allows monitoring systems to track metrics of performance and safety status—including material degradation, doppler feedback and heat pipe performance—while reducing the need for high cost labor from human operators.

“Before deployment, we must ensure that surveillance using digital twins provides accurate information for safe operation within core operating limits,” said Majdi Radaideh, U-M assistant professor of nuclear engineering and radiological sciences and contributing author of the study

Typically, reconstruction methods measure temperature with sensors placed at various points within the reactor and interpolate to estimate temperature in areas not directly measured.

As sparse methods construct the temperature distribution using the lowest number of fundamental modes, or patterns within the data, various approaches to defining these modes can significantly impact the quality of the reconstruction. This study provides guidelines for the evaluation of these approaches with a demonstration on generalized basis functions.

This method aims to reduce computational complexity and the amount of sensor data required while maintaining accuracy. The computer-memory aware nature of the methods will be particularly useful when providing detailed information to digital twin systems with limited computational capabilities.

The researchers evaluated the method with a multiphysics simulation—involving multiple physical processes like nuclear reactions, thermodynamics and fluid dynamics—using generalized basis functions.

Although the method successfully captured broad trends, the generalized basis functions ultimately fell short due to fundamental traits of the reactor system including the spatial variation in heat transfer behavior in materials.

Moving forward, these shortcomings can be addressed using tailored basis functions, meaning basis functions created specifically from precalculated temperature distributions for that microreactor. This would enhance accuracy with robust mathematical integrity.

“Our methods are particularly well suited for remote operation as they take computer memory into account, which will be useful for providing detailed information to digital twin monitoring systems with limited computational abilities,” said Price.