Imagine a stretchable and durable sensor patch for monitoring the rehabilitation of patients with elbow or knee injuries, or an unbreakable and reliable wearable device that measures a runner’s cardiac activities during training to prevent life-threatening injuries.

Disruptive innovations in wearable technology are often limited by the electronic circuits—which are usually made of conductive metals that are either stiff or prone to damage—that power these smart devices.

The newly engineered material, called the Bilayer Liquid-Solid Conductor (BiLiSC), can stretch up to a remarkable 22 times its original length without sustaining a significant drop in its electrical conductivity.

This electrical-mechano property, which has not been achieved before, enhances the comfort and effectiveness of the human-device interface, and opens up a wide array of opportunities for its use in healthcare wearables and other applications.

“We developed this technology in response to the need for circuitry with robust performance, functionality, and yet ‘unbreakable’ for next-generation wearable, robotic, and smart devices,” says Lim Chwee Teck, professor and director of the National University of Singapore’s Institute for Health Innovation & Technology and leader of the research team. “The liquid metal circuitry using BiLiSC allows these devices to withstand large deformation and even self-heal to ensure electronic and functional integrity.”

Lim and his team are also from the biomedical engineering department under the NUS College of Design and Engineering.

BiLiSC is an exciting technology that is ideal for use in wearable devices, which would need to account for the shape, and varied movements, of the body.

It consists of two layers. The first layer is a self-assembled pure liquid metal, which can provide high conductivity even under high strain, reducing the energy loss during power transmission and signal loss during signal transmission.

The second layer is a composite material containing liquid metal microparticles and it is able to repair itself after breakage. When a crack or tear occurs, the liquid metal flowing out from the microparticle can flow into the gap, allowing the material to heal itself almost instantaneously to retain its high conductivity.

To ensure that the innovation is commercially viable, the researchers found a way to fabricate BiLiSC in a highly scalable and cost-efficient manner.

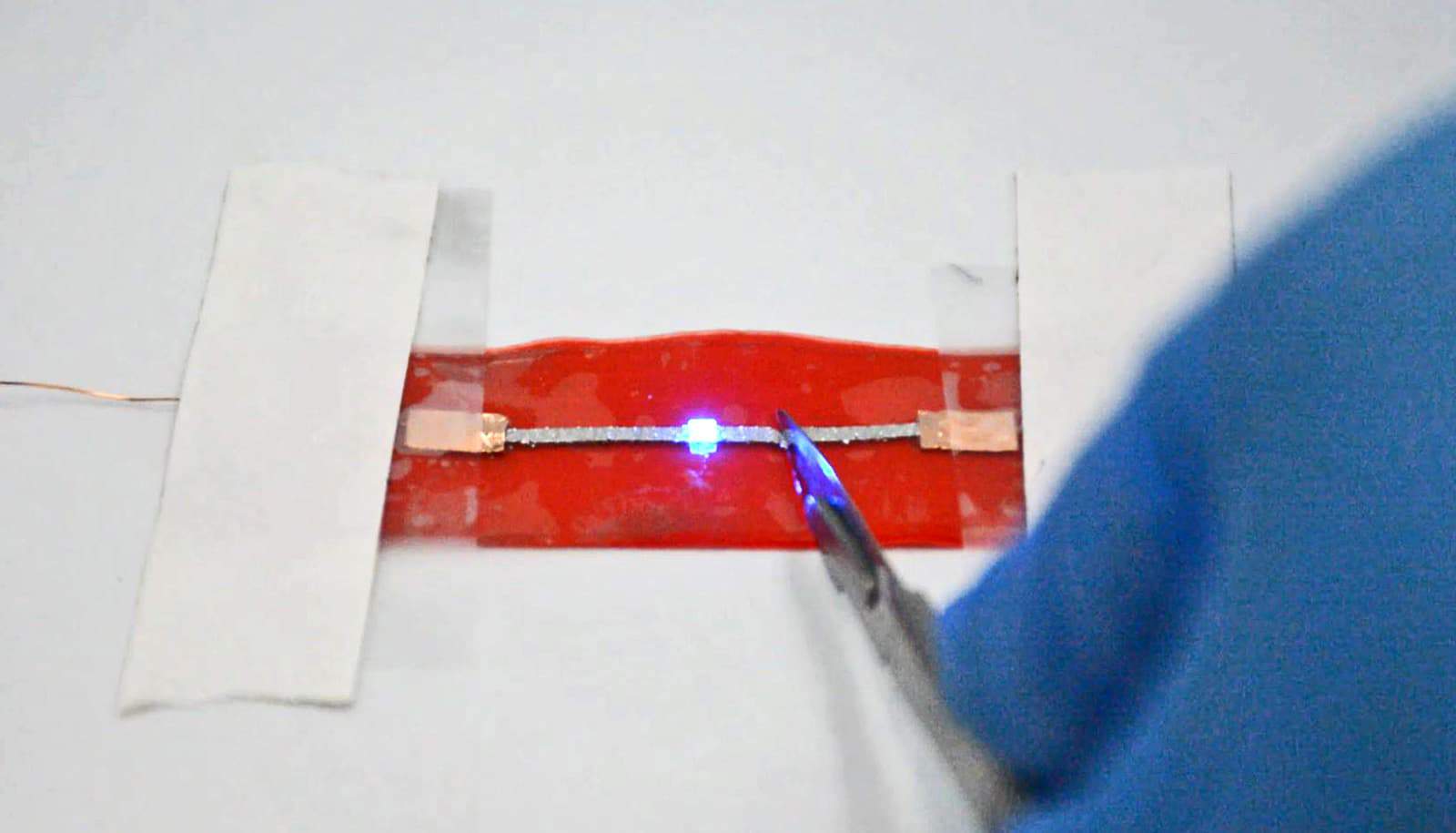

The researchers demonstrated that BiLiSC can be made into various electrical components of wearable electronics, such as pressure sensors, interconnections, wearable heaters, and wearable antennas for wireless communication.

In laboratory experiments, a robotic arm using interconnections was quicker in detecting and responding to minute changes in pressure. In addition, the bending and twisting motion of the robotic arm did not impede the transmission of signals from the sensor to the signal processing unit, compared to another interconnection made with a non-BiLiSC material.

Following the successful demonstration of BiLiSC, the researchers are now working on material innovation and process fabrication. They are looking to engineer an improved version of BiLiS that could be printed directly without needing a template. This would reduce cost and improve the precision in fabricating the BiLiSC.