The solid-state EV battery of the future promises lower cost, longer range, faster charging, and improved safety compared to the EV batteries of today, eventually. Someone still has to figure out how to bundle all those advantages into one package. The startup ProLogium Technology is among those racing for a solution, and the latest development involves a mashup with a century-old automotive supplier.

What’s Wrong With The EV Battery Of Today?

Nothing is particularly wrong with the EV battery of today. However, it is based on a liquid electrolyte, which is the part of a rechargeable battery that ferries lithium ions between two electrodes. The liquid electrolyte for lithium-ion batteries was developed back in the 1990s and the 30-year-old technology is due for a makeover.

Among other issues, liquid electrolytes tend to wind down after a certain number of charging cycles. A more stable, longer lasting EV battery would help address environmental and resource recovery issues in the battery supply chain.

Solid-state EV battery fans also enthuse over the potential for faster charging and higher energy density (see lots more CleanTechnica solid-state battery coverage here).

The “solid” in a solid-state EV battery refers to a solid electrolyte. The technology was first explored in the 1800s and you can probably tell what the problem is, right off the bat. A liquid EV battery can flex itself through numerous charging cycles before it runs out of steam. A solid material has no flex, at least not an ordinary, inexpensive solid material, which explains why 21st century researchers are still struggling to fine tune a 19th-century discovery.

One key breakthrough occurred in June, when the Energy Department’s Oak Ridge National Laboratory in Tennessee took a closer look at a solid lithium phosphorus oxynitride (LiPON) electrolyte developed by the lab in the 1990s. They always knew the solid electrolyte was more stable than its liquid cousins, they just didn’t know exactly why.

Deploying a combo of reflectometry and electrochemistry, the research team determined that a nanoscale layer of about 70 atoms in thickness was the key to forming a stable interphase between LiPON and lithium. The team is already on to the next step, which involves adapting the layer to other types of solid-state electrolytes.

Prologium Comes In Hot On EV Battery Thermal Management

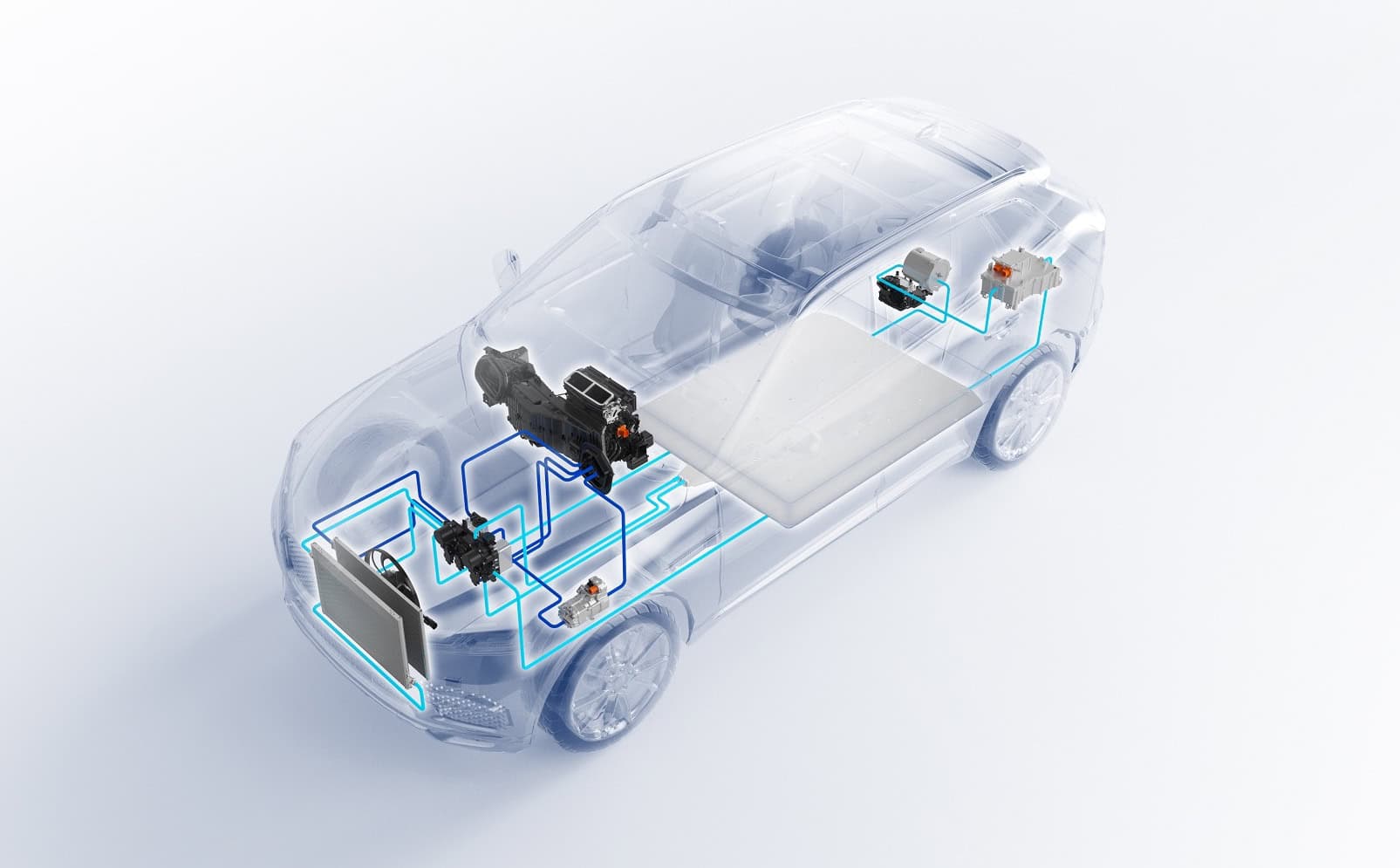

Overheating is one of the challenges involved in designing a liquid-electrolyte EV battery. Thermal management is also an issue for solid-state batteries, and that’s where the latest news from ProLogium comes in.

The Taiwan-based startup unveiled a new iteration of its solid-state EV battery last month, which deploys an oxide ceramic electrolyte. As explained by ProLogium, its battery counts higher heat conductivity and thermal stability among its features, calling for a bespoke thermal management system.

Prologium has enlisted the German firm MAHLE to come up with a tailor-made system for the new battery. This is MAHLE’s first foray into solid-state technology, but the company’s history as an automotive supplier dates back to its founding in 1920. MAHLE points out that about half the vehicles on the road today have at least one MAHLE component under their hoods.

For its part, ProLogium is confident it has made the perfect match. “The partnership between two pioneering companies in the next-generation battery and engineering fields signifies a leap forward in shaping a revolutionary battery value chain, which is crucial for advancing the industrialization of solid-state batteries,” explained ProLogium founder and CEO Vincent Yang.

The venture is focusing on the prototype phase, and if all goes according to plan, the result will be to add the all-important element of commercial viability to the roster of solid-state EV battery benefits.

The joint project will start with a thorough assessment of the ProLogium battery. Depending on how that stage fares, the new “ProLogium-MAHLE” solid-state EV battery will be the end result, sporting ProLogium’s 100% silicon oxide anodes and a thermal management system engineered by MAHLE.

The Long Road To A Commercially Viable EV Battery

There being no such thing as a free lunch, the high performance of solid-state EV batteries comes at a cost. On the bright side, new insights like the one demonstrated by the Oak Ridge lab could speed the R&D process up and accelerate the decline in costs.

Solid-state EV batteries are relatively expensive now, but optimists can point out that the cost of conventional lithium-ion EV batteries also used to be much higher. The US Department of Energy has noted that the cost of an EV battery pack dropped an impressive 89% between 2008 and 2022, calculated with constant 2022 US dollars.

“The 2022 estimate is $153/kWh on a usable-energy basis for production at scale of at least 100,000 units per year. That compares to $1,355/kWh in 2008,” the Energy Department reports. “The decline in cost is due to improvements in battery technologies and chemistries, and an increase in manufacturing volume.”

The figure of $153/kWh is actually a bit higher than the 2020 figure of $143/kWh, partly due to a recent spike in the cost of lithium. Here in the US, that should begin to resolve in the coming years as the nation finally begins tapping into its domestic lithium resources.

The Energy Department is already eyeballing another 50% decline in the cost of EV batteries by 2030, which means that solid-state EV batteries have a lot of ground to make up. Depending on who’s talking, the competitively priced solid-state EV battery of the future is, well, far in the future. Here’s a take by the firm Research and Markets back in 2019:

“…in the initial phase of development, the solid-state technology is estimated to have high cost varying in the range of ~$800/kWh to ~$400kWh by the year 2026. At this level, the solid-state technology is expected to be applicable in premium vehicles, supercars, and luxury cars, as they can easily accommodate such technology in their expansive cost bracket.”

Ouch! On the plus side, higher energy density means that a solid-state EV battery can deliver the same punch as a conventional battery while taking up less space in the vehicle, which could help shave overall vehicle costs. As Prologium points out, solid-state batteries can also help reduce the use of raw materials and cut down on manufacturing waste, helping to push the affordability envelope.

In addition to the high-end market envisioned by Research and Markets, the fleet vehicle market could also provide a welcoming environment for solid-state technology, if the higher cost of the vehicle is offset by the longevity, range, and fast-charging capability of its battery.

If you have any thoughts about that, drop us a note in the comment thread. In the meantime, automotive stakeholders already seem intent on making solid-state batteries happen.