In a discovery that could reduce or even eliminate the use of cobalt—which is often mined using child labor—in the batteries that power electric cars and other products, scientists at the University of California, Irvine have developed a long-lasting alternative made with nickel.

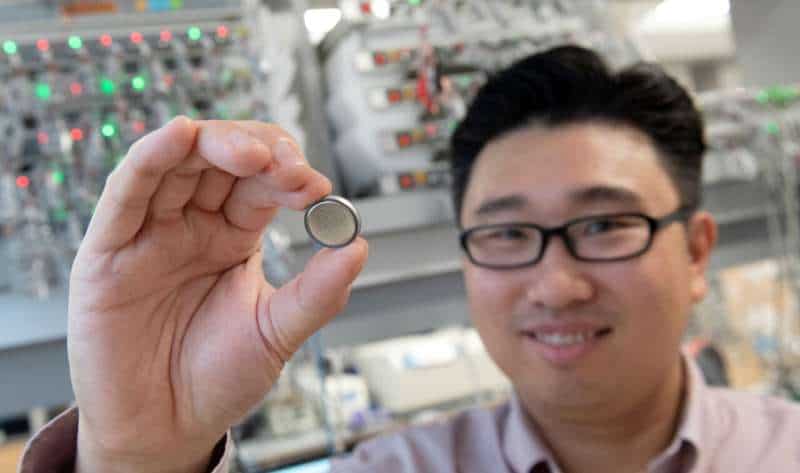

“Nickel doesn’t have child labor issues,” said Huolin Xin, the UCI professor of physics & astronomy whose team devised the method, which could usher in a new, less-controversial generation of lithium-ion batteries. Until now, nickel wasn’t a practical substitute because large amounts of it were required to create lithium batteries, he said. And the metal’s cost keeps climbing.

To become an economically viable alternative to cobalt, nickel-based batteries needed to use as little nickel as possible.

“We’re the first group to start going in a low-nickel direction,” said Xin, whose team published its findings in the journal Nature Energy. “In a previous study by my group, we came up with a novel solution to fully eliminate cobalt. But that formulation still relied on a lot of nickel.”

To solve that problem, Xin’s team spent three years devising a process called “complex concentrated doping” that enabled the scientists to alter the key chemical formula in lithium-ion batteries as easily as one might adjust seasonings in a recipe.

The doping process, Xin explained, eliminates the need for cobalt in commercial components critical for lithium-ion battery functioning and replaces it with nickel.

“Doping also increases the efficiency of nickel,” said Xin, which means EV batteries now require less nickel to work—something that will help make the metal a more attractive alternative to cobalt-based batteries.

Xin said he thinks the new nickel chemistry will quickly start transforming the lithium-ion battery industry. Already, he said, electric vehicle companies are planning to take his team’s published results and replicate them.

“EV makers are very excited about low-nickel batteries, and a lot of EV companies want to validate this technique,” Xin said. “They want to do safety tests.”