Umeå University researchers have made a breakthrough that may make hydrogen—a clean, CO2-free fuel—more affordable. The team has developed a new method that improves how hydrogen gas is produced from water and electricity, a process that’s crucial in our shift toward a more sustainable society.

This major advancement comes from a study led by Eduardo Gracia, a researcher at the Department of Physics at Umeå University. The findings of the study have been recently published in Communications Engineering.

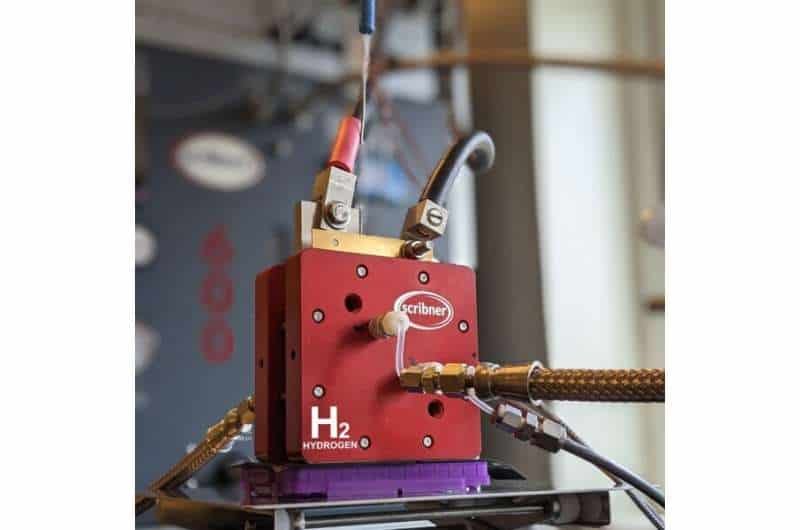

Hydrogen gas is an excellent energy source that can be used to replace fossil fuels. It is produced through a process called water electrolysis where water is split into hydrogen and oxygen. The process requires an electrocatalyst to facilitate the reaction, and nowadays the most efficient technology for such a process is the proton exchange membrane (PEM) water electrolysis.

Metal dissolution: An issue that must be tackled

However, hydrogen production via PEM water electrolysis has a significant issue—it requires the use of noble metals such as platinum, ruthenium, and iridium. Although these metals are good at their job, they are not only expensive and limited in supply, but ruthenium and iridium also tend to break down over time.

“The breakdown of noble metals, a phenomenon known as ‘metal dissolution,’ reduces the effectiveness of hydrogen production. It’s a problem that needs to be solved for us to fully take advantage of PEM technology,” says Associate Professor Eduardo Gracia.

Stabilizing noble metals

So, if PEM technology is expected to drive the transition towards a sustainable society, we first need to tackle the strong electrocatalysts degradation. But how? Well by trapping the highly active but expensive metal in a stable but inactive “scaffold.”

This is where the Umeå team’s breakthrough comes in. The researchers, led by Eduardo Gracia, developed a new scaffold—a kind of supporting structure—that can keep the noble metals stable even under tough conditions.

This scaffold is made of a mixture of tin, antimony, molybdenum, and tungsten oxides (Sn-Sb-Mo-W), which proved to be strong enough to protect not only the noble metals but also other components of the system from breakdown during the process.

By ensuring the noble metals can last longer, the team’s findings can make PEM technology more affordable and effective for large-scale, renewable hydrogen production. This represents a key step in making our transition to a more sustainable society a reality.