The green hydrogen economy is a sustainable alternative to fossil fuels. However, one of the challenges of constructing a global hydrogen economy is hydrogen transportation by sea. A new paper proposes solid air as a medium for recycling cold energy across the hydrogen liquefaction supply chain.

The world is undergoing an energy transition to reduce CO2 emissions and mitigate climate change. The COVID-19 pandemic and the Russia-Ukraine war have further increased the interest of Europe and Western countries to invest in the hydrogen economy as an alternative to fossil fuels. Hydrogen can significantly reduce geopolitical risks if the diversity of future hydrogen energy suppliers is increased.

Hydrogen is a particularly challenging product to transport safely. One option is to liquefy hydrogen, which requires cooling to 20 Kelvin (-253 °C). This is an expensive process and requires around 30% of the energy stored within the hydrogen.

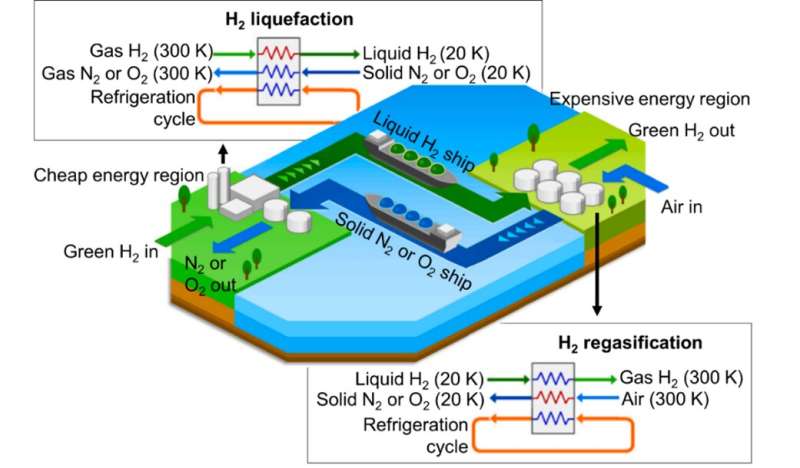

A pioneering approach developed by IIASA researchers and colleagues proposes solid air (nitrogen or oxygen) as a medium for recycling cooling energy across the hydrogen liquefaction supply chain. At standard temperature and pressure, air is a gas, but under certain conditions, it can become a liquid or solid. Solid Air Hydrogen Liquefaction (SAHL) consists of storing the cooling energy from the regasification of hydrogen, by solidifying air, and transporting the solid air back to where the hydrogen was liquefied.

The solid air is then used to reduce the energy consumption for liquefying hydrogen. The process is divided into four main steps: hydrogen regasification, solid air transportation, hydrogen liquefaction, and liquid hydrogen transportation.

Another advantage of solidifying air for energy recovery in the hydrogen liquefaction supply chain is the extra production of oxygen. The oxygen could be used to increase the efficiency of power generation with oxy-combustion and to facilitate the capture, use, and storage of carbon (CCUS).

“Using solid air as a medium for recycling cooling energy across the hydrogen liquefaction supply chain can reduce the cost and energy consumption for transporting hydrogen between continents,” says lead author Julian Hunt, a researcher in the Integrated Assessment and Climate Change Research Group of the IIASA Energy, Climate, and Environment Program.

“This would increase the viability of a global hydrogen economy in the future and increase the number of hydrogen suppliers for energy-demanding regions, such as China, Europe, and Japan. The possibility of selling hydrogen could result in a further expansion of solar and wind power in developing countries, contributing to their economies.”

In their paper, the authors also address the ongoing debate in industry and academia to find the best alternative to transport hydrogen by sea: “Compared to ammonia or methanol, liquefied hydrogen is the best option for several reasons. Transporting hydrogen with ammonia and other molecules would require around 30% of the energy transported to extract the hydrogen. The hydrogen is liquefied where electricity is cheap. Also, SAHL can lower energy consumption for hydrogen liquefaction by 25 to 50%,” Hunt concludes.

The findings are published in the International Journal of Hydrogen Energy.