When you take a trip on a plane, train or cruise ship you likely are traveling by the power of gas turbines. These are combustion engines that convert gas or liquid fuel to mechanical energy. The process involves air, fuel, compression and fire. While these modern power-generators are common and reliable, scientists still work to better understand how gas turbines operate in order to make them better.

With this in mind, a team of researchers from Georgia Institute of Technology (Georgia Tech) used both Expanse at the San Diego Supercomputer Center at UC San Diego and Bridges-2 at the Pittsburgh Supercomputing Center for simulations to show new ways to develop more efficient and cleaner gas turbine combustion systems. Expanse was also used to store the large simulation files.

The study, titled “Influence of Mixture Composition and Radial Flame Location on Counter-rotating Vortex Pair Evolution in a Reacting Jet in Crossflow,” has been published in the American Institute of Aeronautics and Astronautics (AIAA) SciTech 2023 Forum Proceedings, AIAA SCITECH 2023 Forum.

“Access to supercomputers through programs like XSEDE/ACCESS have given us free allocations to run these large simulations that would otherwise take a long time to run,” said Vishal Acharya, co-author and associate director of the Aerospace Combustion Laboratory at Georgia Tech’s School of Aerospace Engineering. “National systems like Expanse and Bridges-2 that are accessible through XSEDE/ACCESS are well set up for these simulations and they are only getting faster—we have saved a lot of time using them and the free access also means we save research dollars.”

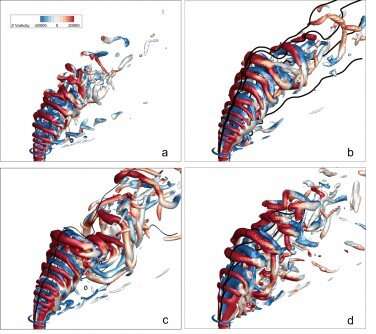

The simulations helped the research team address the role of combustion and its interaction with the jet shear layer—the region responsible for the formation of turbulent structures and vortices which control the mixing and the spreading of the thickness and speed of a fluid over time and space (i.e., the “flowfield”). The study also demonstrated that under certain conditions, the entire topology of the flowfield can completely change with large implications to the mixing performance of the flow.

“Our study not only analyzed the impact of combustion on the flow structure and flow physics for a novel set of conditions, but also provides important guidance for the development of systems that emit smaller amounts of pollution,” said Vedanth Nair, lead author and research engineer in the Georgia Tech Aerospace Combustion Lab.

“The flow configuration analyzed in the study—the jet in crossflow—is a canonical flow field that can be observed in multiple practical systems specifically in gas turbines where its objective is to efficiently mix two streams of dissimilar fluids such as fuel into a hot crossflow or cooling air into combustion gases.”

Acharya said that the study is part of a larger program using both experimental and computational tools to study the complex reacting fluid mechanics in a jet-in-cross-flow that can help improve their use in varying combustion systems. While the computational tools allow the team to carefully change each parameter to analyze specific fluid mechanic effects of combustion, the experiments provide real-life context to observed flow structures.

“The results of our experiments showed us that combustion has a significant impact on the flow structure under the conditions we considered in our simulations,” Nair said. “In addition, it demonstrated an additional parameter that was critical to consider while studying reacting jets in crossflow—the Reynolds number of the jet, which is a measure of the inertial versus viscous tendencies of the jet.”

The team’s current work is taking this research a step further with plans to capture the effect of viscosity/Reynolds number on the particular flame-flow configuration and extending the operating conditions so that they are in line with more practical gas turbine systems. Again, they plan on using supercomputers for simulation.