A report by South Korea’s TheElec claims that General Motors is planning to stop using pouch cells in its future electric cars and switch to cylindrical cells. The move has caused some stress in the relationship between GM and its primary battery supplier, LG Energy Solution. The two companies are have already agreed to jointly construct and operate three battery factories in the US. One is already in operation in Ohio and two others are under construction — one in Michigan and the other in Tennessee.

A fourth factory was planned for Indiana, but this latest decision seems to have put that plan on hold. The talks between GM and LGES about that plant have ended, sources tell TheElec, and GM is reportedly reaching out to at least one other battery manufacturer, as yet unnamed.

There are precious few details available but the information TheElec got from its sources in South Korea is that General Motors will use the 4680 format cylindrical cells first used by Tesla. Cylindrical cells may be somewhat easier to manufacture than pouch cells, since the production techniques have been in use since the Carter administration, which could make them a lower cost option at a time when battery materials prices are rising.

The 4680 Cell

Kyle Field introduced CleanTechnica readers to the Tesla 4680 battery cell in September of 2020. He wrote that the new form factor eliminates the tabs, increases energy density, maintains similar thermal characteristics of smaller cells, improves the power-to-weight ratio, streamlines manufacturing, and lowers cost. That’s a lot of good reasons to use them. In January, 2021, we gave our readers an inside look at the 4680 battery manufacturing process Tesla is using.

At that time, Iqtidar Ali wrote, “One intriguing idea behind the 4680 cell is its 80 mm height which enables continuous motion cell manufacturing — similar to bottle production at beverage companies. This speeds up cell production compared to current procedures practiced at Giga Nevada’s cell manufacturing facility.”

Since then, every one and his cousin has been jumping into the 4680 format battery cell game. Panasonic, Tesla’s partner at the Nevada Gigafactory, got busy right away by designing a prototype 4680 cell for Tesla. Kazuo Tadanobu, head of Panasonic’s energy business, said in October, 2021, “We have developed this because of the strong desire of the other party, and we think this can only lead to stronger ties.” That may be so, but it also gives Panasonic a leg up on the competition to supply similar batteries to other companies.

CATL is the world’s largest battery manufacturer and it hasn’t exactly been standing still while Panasonic eats its lunch. Last March, it introduced what it calls its Kirin battery pack which Wu Kai, chief scientist for CATL, said has 13% more power than a battery pack using 4680 cells. It’s not that the individual battery cells are more powerful, it’s that CATL’s third generation cell-to-pack technology squeezes more power into the same space occupied by a 4680 battery pack.

The secret is in the packaging, not a new breakthrough in battery chemistry. Wu said the Kirin battery leads the industry in system weight, energy density, and volumetric energy density. “We have analyzed the range distribution of passenger cars in the last three years and found that consumers’ quest for long range is still a trend,” he added.

Since then, Tesla has found that scaling up production of its 4680 batteries is taking somewhat longer than expected. Being first out of the gate does not mean being first across the finish line. Meanwhile, last June, Samsung SDI announced it too would manufacture battery cells that are 46 millimeters in diameter, but would offer them in both 40 millimeter and 60 millimeter lengths, which would give automakers more choices when designing electric cars.

TheElec reported at the time that companies could stack two levels of 4640 cells one on top of the other to create a dual level battery pack. While that arrangement may be somewhat heavier and cost more than a single layer of 4680 cells, it could offer other benefits such as better control of battery cell temperatures within the battery pack. The 4660 cells would allow a manufacturer to have a somewhat lower floor height in a finished car.

Indeed, in June of last year, BMW announced it was transitioning away from the prismatic cells it had been using in its electric cars and would use cylindrical battery cells that are 48 mm in diameter and of various lengths to fit the needs of various new models going forward.

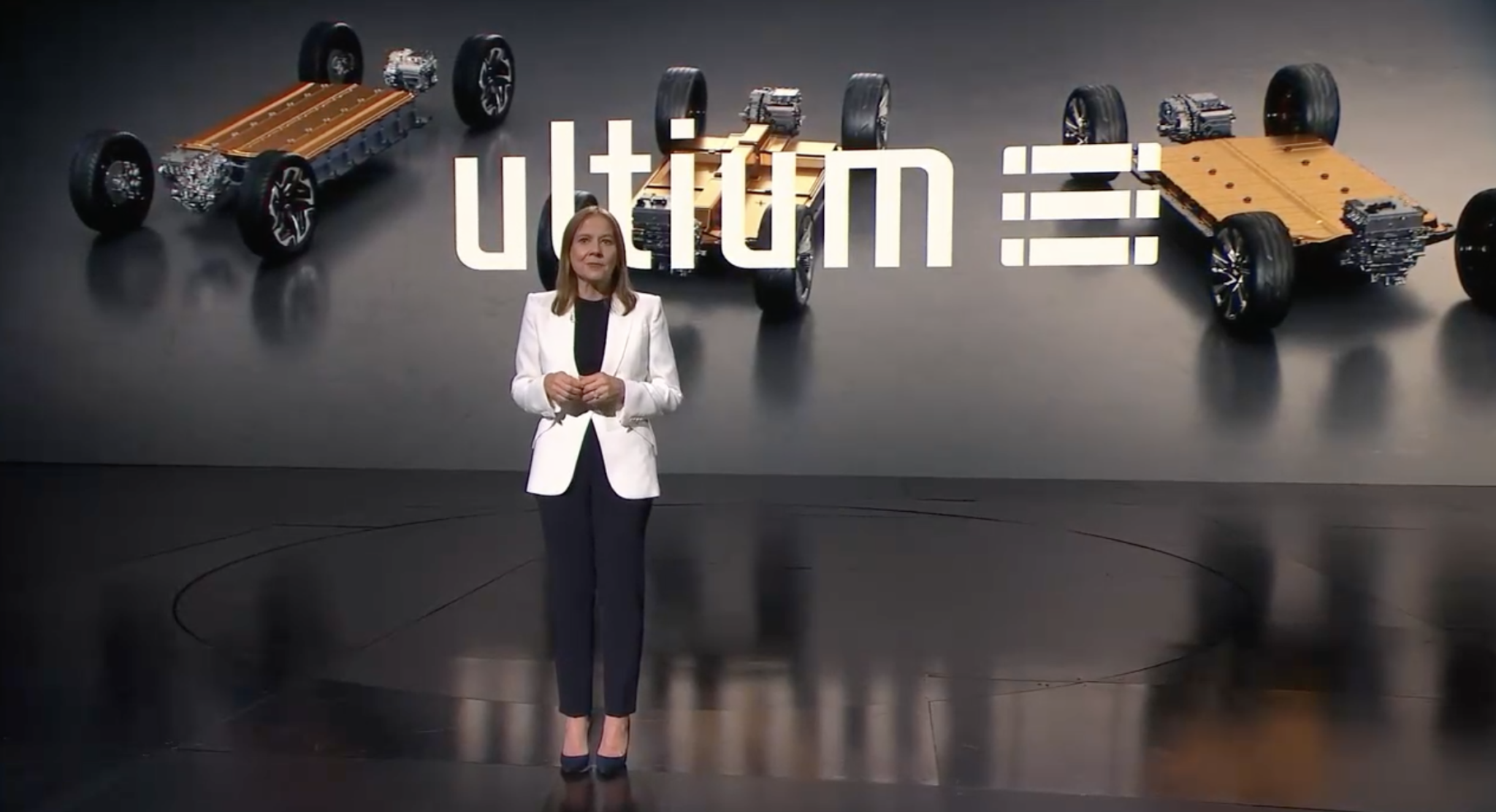

What About Ultium?

When GM rolled out its Ultium battery technology, the PR types went wild, extolling its virtues to the skies. Here is how Ultiuim batteries were described in a company presentation:

- Unlike traditional cylindrical battery cells, our high-energy pouch cells have a modular design.

- Ultium’s long pouch cells waste less space and can stack on top of each other like pancakes or vertically like slices of toast. This simple modular design makes it easy for engineers to optimize energy density and vehicle layout, which translates to more miles on a single charge for less cost.

- Our Ultium cells pack a punch! It would take 20 small cylindrical can cells (the ones our competitors use) to produce the power of one Ultium large-format 100 amp-hour cell. Our Ultium cells are so robust, they can electrically and physically support EVs of every shape and size.

- Our battery options scale from 50 kilowatt hours to over 200 kWh, which will enable a GM-estimated range of 300 miles or more on a full charge.

But wait, there’s more! According to GM:

- Stacking battery pouch cells enables flexible engineering…and a more comfortable ride!We’ll engineer some of America’s most popular vehicles (think trucks, SUVs and crossovers) with vertically-stacked cells – like toast, whereas performance vehicles, which are deeply embedded in our DNA, may include horizontally-stacked cells – like pancakes. GM’s ability to stack long pouch cells vertically or horizontally in modules is unique in the industry.

- To save even more space, the battery’s electronic components will be embedded within the modules, eliminating 80 percent of the battery pack wiring compared to today’s batteries.

- We reduced the height of the battery module underneath the second row, which will not only give second-row passengers a more comfortable ride, but also adds 22 kWh of energy storage in this space.

Now all that wonderfulness is out the window. Pouch cells are out and cylindrical cells are in. The world of public relations is a bizarre and mysterious place!

Do we know who GM will turn to for its 4680 battery cells? No, we do not, although Samsung SDI must certainly be in the running.

The partnership between LG and GM is a long standing one. LG built most of the internal workings of the original Chevy Bolt, including the dashboard. And what of those 3 battery factories the two companies are building? Will they manufacture pouch cells or cylindrical cells? No one knows. There is more to this story than meets the eye and we will keep our readers informed as we learn more.