Researchers at the Department of Energy’s Oak Ridge National Laboratory and the University of Tennessee, Knoxville, discovered a key material needed for fast-charging lithium-ion batteries. The commercially relevant approach opens a potential pathway to improve charging speeds for electric vehicles.

Lithium-ion batteries, or LIBs, play an essential role in the nation’s portfolio of clean energy technologies. Most hybrid electric and all-electric vehicles use LIBs. These rechargeable batteries offer advantages in reliability and efficiency because they can store more energy, charge faster and last longer than traditional lead-acid batteries. However, the technology is still developing, and fundamental advances are needed to meet priorities to improve the cost, range and charge time of electric-vehicle batteries.

“Overcoming these challenges will require advances in materials that are more efficient and synthesis methods that are scalable to industry,” said ORNL Corporate Fellow and corresponding author Sheng Dai.

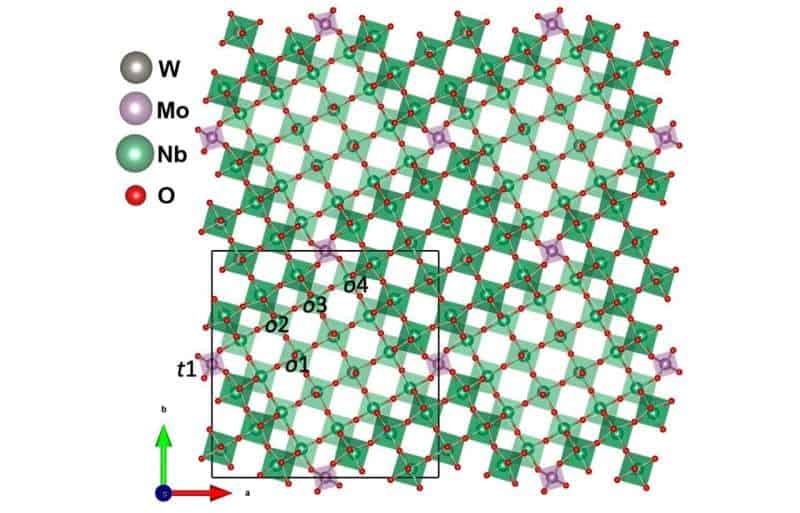

Results published in Advanced Energy Materials demonstrate a novel fast-charging battery anode material achieved by using a scalable synthesis method. The team discovered a novel compound of molybdenum-tungsten-niobate, or MWNO, with fast rechargeability and high efficiency that could potentially replace graphite in commercial batteries.

For decades, graphite has been the best material used to make LIB anodes. In basic battery design, two solid electrodes—a positive cathode and a negative anode—are connected by an electrolyte solution and a separator. In LIBs, lithium ions move back and forth between the cathode and anode to store and release energy that powers devices. One challenge for graphite anodes is that the electrolyte decomposes and forms a buildup on the anode surface during the charging process. This buildup slows the movement of lithium ions and can limit battery stability and performance.

“Because of this sluggish lithium-ion movement, graphite anodes are seen as a roadblock to extreme fast charging. We are looking for new, low-cost materials that can outperform graphite,” said ORNL postdoctoral researcher and first author Runming Tao. DOE’s extreme fast-charging goal for electric vehicles is set at 15 minutes or less to compete with refuel times on gas-powered vehicles, a milestone that has not been met with graphite.

“Our approach focuses on nongraphite materials, but these also have limitations. Some of the most promising materials—niobium-based oxides—have complicated synthesis methods that are not well suited to industry,” Tao said.

Conventional synthesis of niobium oxides such as MWNO is an energy-intensive process over open flame that also generates toxic waste. A practical alternative could push MWNO materials to become serious candidates for advanced batteries. Researchers turned to the well-established sol-gel process, known for safety and simplicity. Unlike conventional high-temperature synthesis, the sol-gel process is a low-temperature chemical method for converting a liquid solution into a solid, or gel, material and is commonly used to make glasses and ceramics.

The team transformed a mixture of ionic liquid and metal salts into a porous gel that was treated with heat to enhance the material’s final properties. The low-energy strategy also enables the ionic liquid solvent used as a template for MWNO to be recovered and recycled.

“This material operates at a higher voltage than graphite and is not prone to forming what is called a ‘passivation solid electrolyte layer’ that slows down the lithium-ion movement during charging. Its exceptional capacity and fast-charging rate, combined with a scalable synthesis method, make it an attractive candidate for future battery materials,” said Tao.

The key to the material’s success is a nanoporous structure that provides enhanced electrical conductivity. The result offers less resistance to the movement of lithium ions and electrons, enabling fast recharging.

“The study achieves a scalable synthesis method for a competitive MWNO material as well as providing fundamental insights on future design of electrode materials for a variety of energy storage devices,” said Dai.