Researchers from Tokyo Metropolitan University have demonstrated that electrochemical impedance spectroscopy (EIS) can be a powerful non-destructive tool to study the degradation mechanisms of all-solid-state lithium metal batteries. They studied ceramic-based all-solid-state Li metal batteries prepared by aerosol deposition and heating, identifying the specific interface responsible for the drop in performance. Published in ACS Applied Materials & Interfaces, their work accurately highlights the engineering hurdles that need to be overcome to bring these top-in-class batteries to the market.

Electric vehicles (EVs) are a crucial part of efforts worldwide to cut carbon emissions. And at the heart of every EV is its battery. Battery design remains a key bottleneck when it comes to maximizing driving range and improving vehicle safety. One of the proposed solutions, all-solid-state lithium metal batteries, has the potential to provide higher energy density, safety, and lower complexity, but technical issues continue to hamper their transition into everyday vehicles.

A major problem is the large interfacial resistance between electrodes and solid electrolytes. In many battery designs, both cathode and electrolyte materials are brittle ceramics; this makes it difficult to have good contact between them. There is also the challenge of diagnosing which interface is actually causing problems. Studying degradation in all-solid-state lithium metal batteries generally requires cutting them open: this makes it impossible to find out what is happening while the battery is operating.

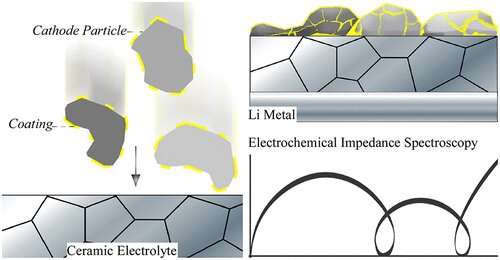

A team led by Professor Kiyoshi Kanamura at Tokyo Metropolitan University have been developing all-solid-state Li metal batteries with lower interfacial resistance using a technique called aerosol deposition. Microscopic chunks of cathode material are accelerated towards a layer of ceramic electrolyte material where they collide and form a dense layer.

To overcome the issue of cracks forming on collision, the team coated the chunks of cathode material with a “solder” material, that is, a softer, low melting point material which can be heat treated to generate excellent contact between the newly formed cathode and electrolyte. Their final all-solid-state Li/Li7La3Zr2O12/LiCoO2 cell delivers a high initial discharge capacity of 128 mAh g-1 at both 0.2 and 60 °C and maintains a high-capacity retention of 87% after 30 charge/discharge cycles. This is a best-in-class result for all-solid-state Li metal batteries with ceramic oxide electrolytes, making it all the more important to really get to grips with how they might degrade.

Here, the team used electrochemical impedance spectroscopy (EIS), a widely used diagnostic tool in electrochemistry. By interpreting how the cell responds to electrical signals of different frequency, they could separate out the resistances of the range of different interfaces in their battery. In the case of their new cell, they found that a resistance increase between the cathode material and the solder was the main reason for cell capacity decay. Importantly, they achieved this without tearing the cell apart. They were also able to back this up using in-situ electron microscopy, clearly identifying interface cracking during cycling.

The team’s innovations have not only realized a cutting-edge battery design but highlighted the next steps for making further improvements using a damage-free, widely available method. Their new paradigm promises exciting new advances for batteries in the next generation of EVs.